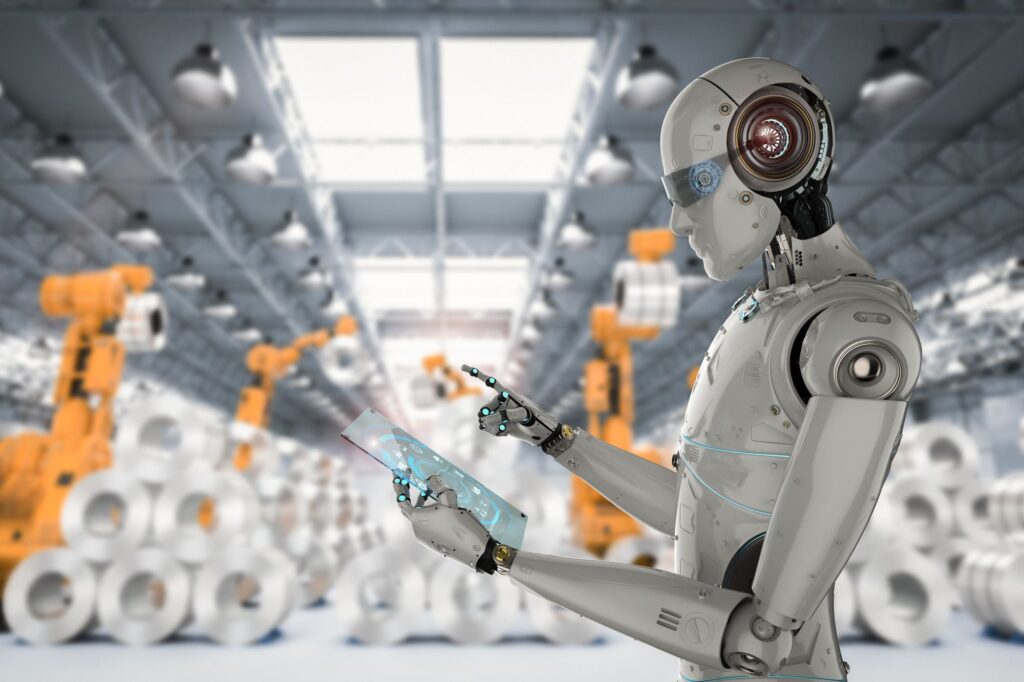

Introduction to Industrial Robotics

The automation era has changed industries’ operations, driving a revolution centered around efficiency and precision. Industrial robotics is at the heart of this revolution – an amalgamation of engineering, technology, and science that has disrupted traditional production methods.

The Evolution of Industrial Robotics

Industrial robotics have come a long way since their inception. The progress is clear when looking at their two critical evolution phases.

-

First-Generation Robots

The pioneers of industrial robots were basic, limited to straightforward tasks such as pick and place operations. They could not adapt to different tasks and environments.

-

The Technological Revolution of the Twenty-First Century

The new century heralded a period of extraordinary technical progress. Industrial robots capable of executing complicated tasks with great accuracy and flexibility have been built by combining robotics with cutting-edge technology such as AI and machine learning.

Applications of Industrial Robots

Industrial robots find a wide range of applications across sectors.

-

Manufacturing

Robots automate repetitive tasks, enhancing production speed and quality in automobile manufacturing, electronics, and food processing industries.

-

Warehousing and Logistics

Industrial robots streamline inventory management and order fulfillment, transforming the logistics industry.

-

Health and Safety

In hazardous environments, robots can operate without risking human life, improving overall safety standards.

Key Components of Industrial Robots

Industrial robots comprise three fundamental components.

-

The Controller

Often called the ‘brain,’ the controller executes commands and controls the robot’s movements.

-

The Arm

The ‘body’ of the robot, the arm, carries out physical tasks with precision and flexibility.

-

End Effectors

End effectors, or ‘hands,’ vary based on the task – they may be grippers, welders, or even paint sprayers.

Benefits of Industrial Robots

-

Efficiency and Productivity

Robots work tirelessly, leading to increased productivity and efficiency.

-

Quality Assurance

With precision and consistency, robots reduce errors, improving product quality.

-

Workplace Safety

By undertaking dangerous tasks, robots reduce workplace accidents.

The Future of Industrial Robots

-

Artificial Intelligence and Robotics

Artificial Intelligence integration in robotics will lead to ‘smarter’ robots that learn and adapt, taking automation to new heights.

The Emergence of Collaborative Robots

Cobots, designed to work alongside humans, are gaining traction and may soon become the norm.

Conclusion

Industrial robotics is reshaping industries, bringing about profound changes in our work. As the technology evolves, its impact will only grow, promising an exciting future.