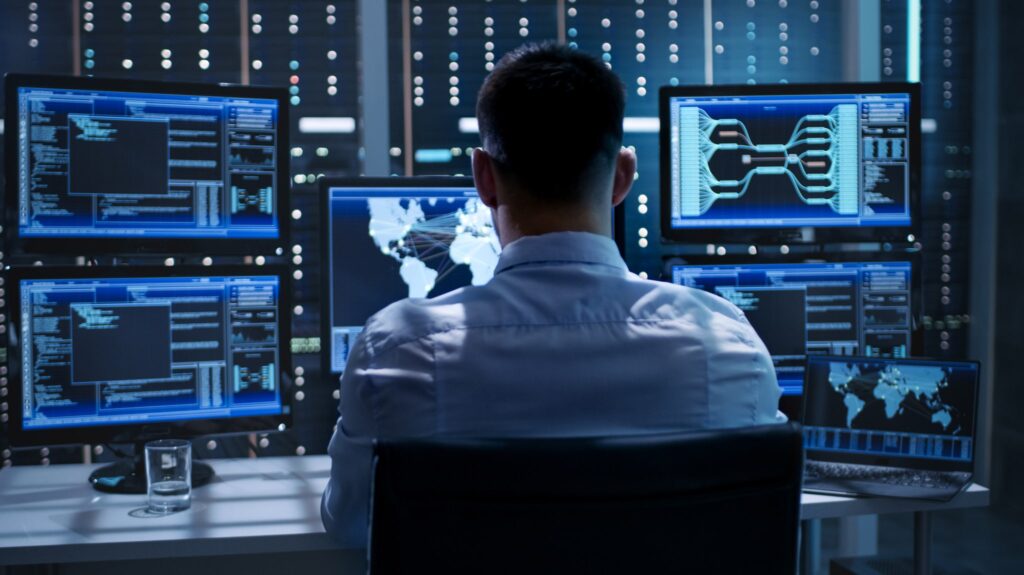

Definition of Industrial Control Systems

Industrial Control Systems Cybersecurity combines hardware and software that oversee and regulate industrial operations. They’re essential in manufacturing, power generation, water treatment, etc.

Importance of ICS in Industries

ICS systems are the backbone of many industries. They provide precision, efficiency, and reliability, enabling industries to operate seamlessly and safely. But what happens when these systems become targets for cyber threats?

Understanding Cybersecurity

-

The Need for Cybersecurity in ICS

Like any other system connected to a network, ICS is not immune to cyber threats. The consequences of a successful cyber-attack on these systems can be catastrophic. Hence, implementing robust cybersecurity measures becomes imperative.

-

Consequences of Poor Cybersecurity in ICS

Imagine a scenario where a power grid gets hacked. This could lead to blackouts, chaos, and significant economic losses. That’s the potential impact of inadequate ICS cybersecurity.

Common Threats to Industrial Control Systems Cybersecurity

-

External Threats

External threats come from hackers, cybercriminals, or nation-states. They may seek to disrupt operations, steal sensitive information, or cause harm for political or financial gain.

-

Internal Threats

Not all threats originate from outside. Employees, either due to negligence or malicious intent, can also pose a threat. For instance, using weak passwords or clicking on phishing emails can provide a gateway for cyberattacks.

Mitigating Threats to Industrial Control Systems Cybersecurity

-

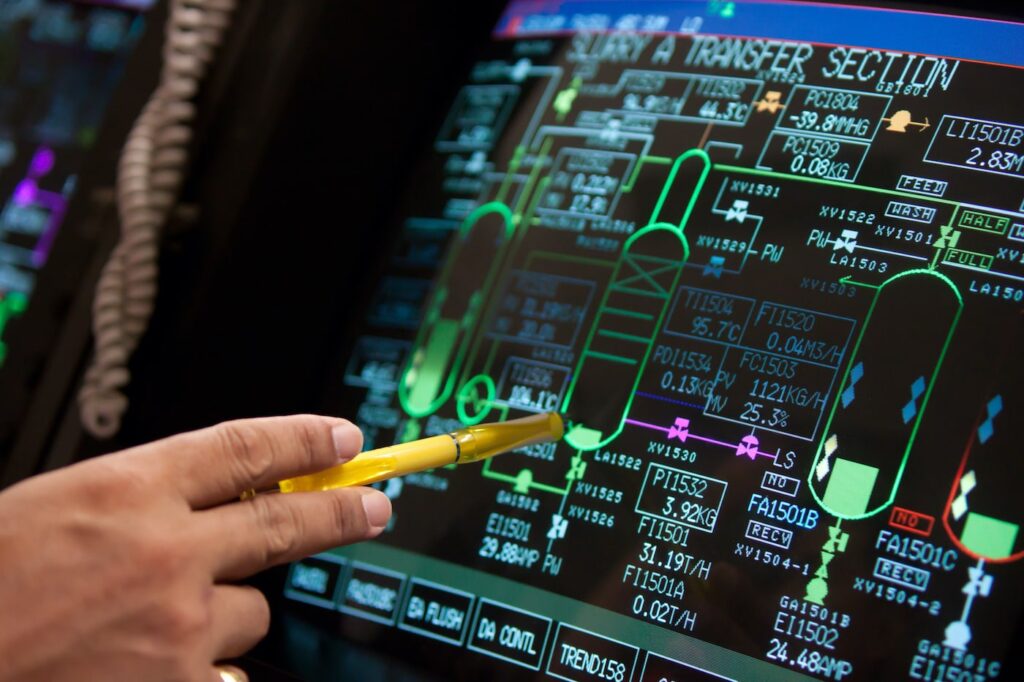

Identifying Vulnerabilities

The first step in mitigating threats is identifying potential vulnerabilities. Regular assessments and penetration testing can help detect weaknesses before hackers do.

-

Developing and Implementing Security Policies

Having comprehensive security policies is essential. Policies should cover access control, encryption, firewall settings, and more.

-

Regular Monitoring and Auditing

Constant monitoring and periodic auditing of ICS can detect anomalies early, preventing potential attacks or minimizing their impact.

Best Practices for Industrial Control Systems Cybersecurity

-

Employee Training and Awareness

People are often the weakest link in CybersecurityCybersecurity. Regular training programs can update employees on the latest threats and best practices to mitigate them.

-

Multi-Factor Authentication

Implementing multi-factor authentication adds an extra layer of security, making it harder for unauthorized persons to gain access.

-

Regular Patching and Updating

Software vulnerabilities are common targets for hackers. Regularly patching and updating all software components is key to closing these security gaps.

-

Incident Response Planning

Despite the best efforts, breaches can occur. A robust incident response plan can help mitigate the damage and recover quickly.

The Future of Industrial Control Systems Cybersecurity

-

Evolving Threat Landscape

The threat landscape is constantly evolving. As technology advances, so do the capabilities of hackers. Staying ahead requires continuous vigilance and adaptation.

Emerging Technologies and Their Impact

The use of emerging technologies like AI and machine learning is being employed to improve cybersecurity for ICS. However, malicious actors can also exploit them, presenting new challenges.

Conclusion

The importance of Industrial Control Systems cybersecurity cannot be overstated. As we rely more on these systems, security becomes critical. Maintaining a strong cybersecurity posture may seem daunting, but following best practices and keeping up with the latest developments can greatly help.